I never want to ship somebody a bag of parts and say “Good luck,” leaving them to interpret resistor color bands and capacitor codes. But I understand why so many kit suppliers do it.

Sorting and individually packing components is VERY time consuming, and more time means higher costs.

I don’t want the kits to be too expensive either, so I’m always trying to strike a balance.

The Old (and sometimes current) Method

For most of MAS Effects’ time offering DIY kits, I’ve packed components in labeled bags, but minimized bags by putting unambiguously different components in the same bag. e.g. a single resistor + a strip of 2 resistors + a capacitor. With a bit of inference you can easily figure out which is which.

This is pretty time consuming and costly though. Sure it’s better and less wasteful than individually bagging each component, but not by much.

A Short-lived Experimental Method

I tried something new this fall, taping components to a sheet. It’s quicker, but has a couple of trade offs:

sometimes the tape fails to hold and you end up with loose parts

it doesn’t look great

It’s also a bit easier to get parts mixed up, like when a resistor rolls from one pile to another.

I scrapped this after a very short trial, but still have stacks of these sheets already printed, so your kits may include these early versions with little scissors icons on the dotted lines. The idea was that you could cut the rectangles out if that made it easier for you to organize.

Our Current (Trial) Method

Here’s the current iteration in finding the ideal blend of…

Quick and easy kit building process for you

Reduced waste

Less time (cost) putting the kits together

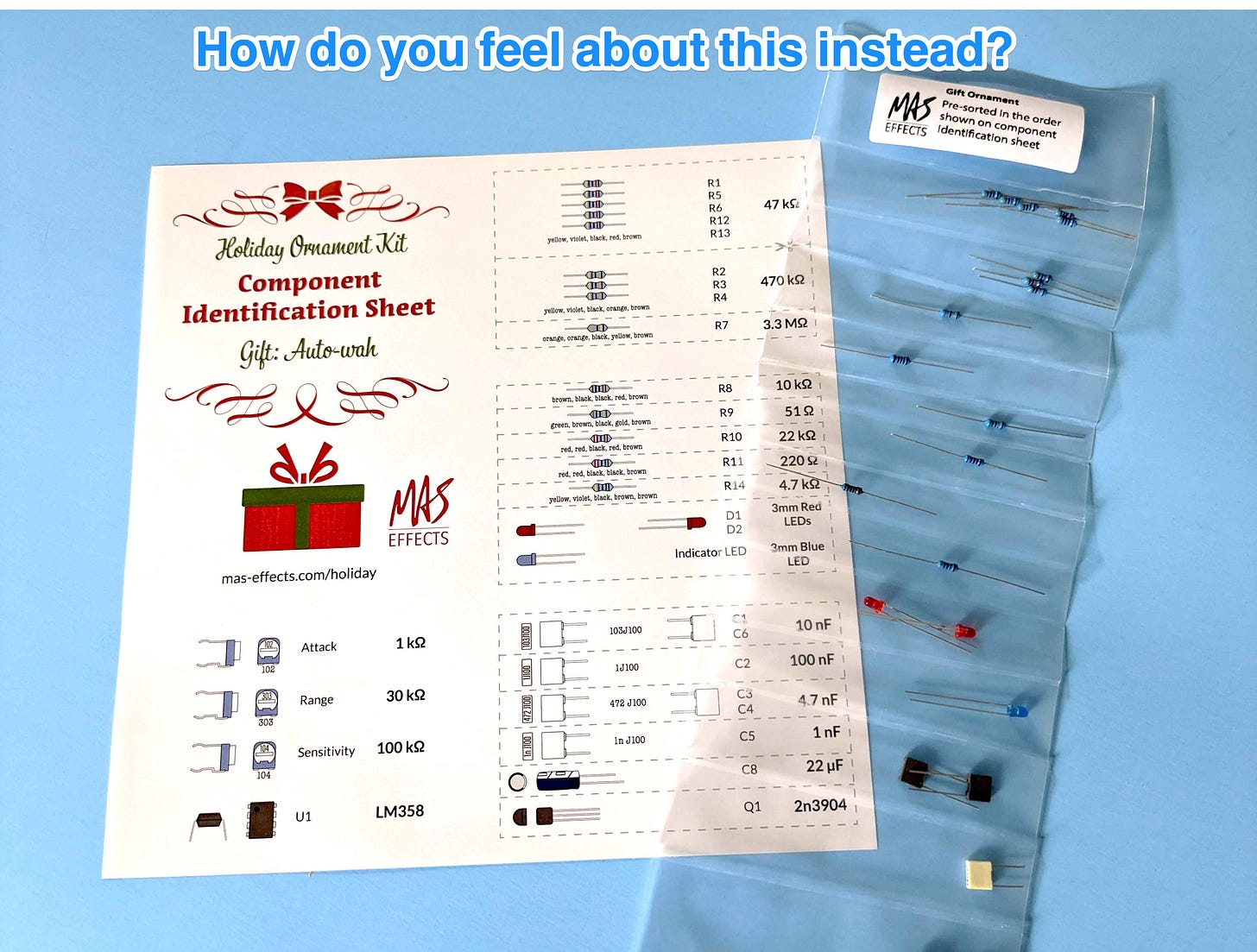

Now we’re heat sealing the components in a sleeve, pre-sorted and grouped in the order shown on an included Component Identification Sheet.

When it comes time to build, it’s probably easiest for you to cut the sides off the sleeve. As you build you can pull out the components as you need them.

What Do You Think?

Hit me up in the comments or reply directly to share your thoughts. Do you think this will work well for you? Or should we stick with the zipper bags? Or go even further and individually bag each component?

How the Sausage is Made

If you’re curious, this is how it’s done. It’s a small, simple, impulse sealer. I drop the first component into each of the sleeves, seal them, then move on to the second component. Rinse and Repeat.

Mark, I think that looks like a very usable method. Zip locks are great but the quantities that I order from Tayda and others almost dictate that. With you supplying kits for individual projects I think your new way of packaging the components makes a lot of sense. I think this way is an easy way for a user to survey the parts and doesn't generate the bag of bags I now have to store in my lab. Keep doing great things. Regards!